As large-scale battery energy storage systems (BESS) rapidly expand across the globe, concerns about their safety have never been more urgent. Recent high-profile incidents at battery energy storage facilities in the U.S. have underscored the growing challenges of safely managing large-scale systems[1].

In response, regulators have introduced stringent safety standards such as NFPA 855, requiring proper installation, hazard mitigation analysis, and fire suppression systems before any facility becomes operational.

Building on these requirements, HiTHIUM has recently completed the industry’s first large-scale fire test with fully open doors on its ∞Block 5MWh battery energy storage system—a breakthrough moment that redefines transparency and BESS fire safety standards across the industry.

This article dives into HiTHIUM’s success, revealing key insights into next-generation fire-safe BESS design and how innovation is pushing safety beyond regulatory minimums.

Battery Fire Testing

What Is Battery Fire Testing and What Are the Limitations Today?

What UL 9540A and NFPA 855 Call Battery Fire Testing

Battery fire testing, as defined by UL 9540A, is a laboratory procedure designed to intentionally induce thermal runaway in lithium-ion cells, modules, battery units, and complete energy storage systems. During these controlled burn tests, critical data such as flame length, heat release rate, gas composition, and pressure increase are meticulously measured.

Following these tests, NFPA 855 mandates that project teams submit UL 9540A results to local fire authorities. These findings guide fire marshals in establishing safety requirements, including minimum spacing, fire suppression systems, and other installation parameters. This systematic testing process is commonly referred to within the industry as battery fire testing.

Why Current Tests Stay Behind Closed Doors

Most battery fire tests are still conducted within sealed steel containers or enclosed walk-in chambers. These environments are tightly controlled: doors are locked, and ventilation rates are fixed by the testing facility. While limiting oxygen helps contain flames and protect sensitive equipment, it also suppresses real-world fire behavior—starving the fire and restricting the data that engineers can observe.

In an actual incident, the failure of a door, vent, or panel can rapidly introduce oxygen, triggering a sudden flashover. This escalation is rarely captured in closed-door tests, creating a significant gap between laboratory conditions and real-world fire dynamics. Today, that disconnect has become one of the most frequently cited criticisms of conventional battery fire testing.

Taking the Doors Off: Open‑Door Test

Open-door fire tests challenge conventional protocols by intentionally keeping the battery cabinet fully open, allowing unrestricted airflow to feed the flames. This approach exposes battery systems to harsher, more realistic conditions, offering a tougher benchmark for evaluating thermal risk and fire containment.

What Makes HiTHIUM's Open-Door Fire Test Groundbreaking?

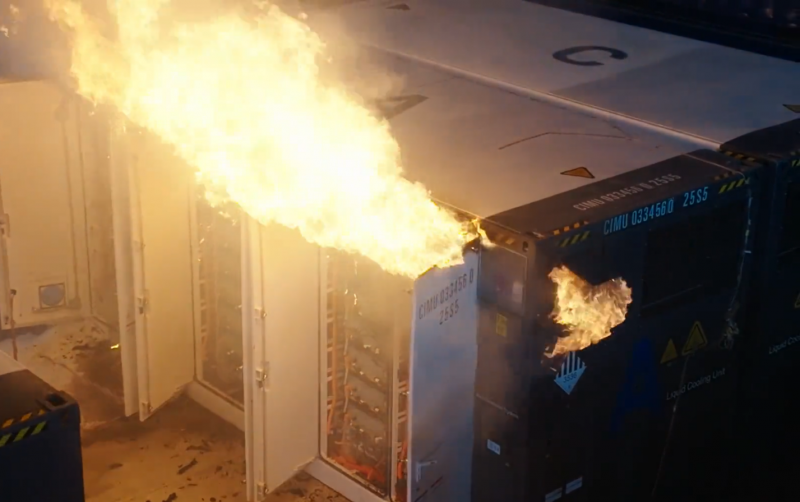

In this test, HiTHIUM subjected its system to a combination of extreme, real-world conditions: all container doors remained fully open, the fire suppression system was deliberately disabled, and the unit was charged to 100% state of charge (SOC) prior to ignition. The battery energy storage systems were arranged with dual extreme spacing, placed side by side and back to back at just 15cm apart.

Despite temperatures exceeding 1,300°C and 15 continuous hours of combustion, the fire was fully contained within the initiating cabinet, demonstrating the system’s ability to prevent thermal propagation even under worst-case scenarios.

By removing conventional containment and suppression barriers, this open-door test exposed the system to harsher conditions than standard fire testing. The result: higher flames, longer burn durations, and greater volumes of gas, providing a tougher, lifelike test of lithium-ion battery thermal risk. It marks a critical step forward in bridging the gap between lab testing and real-world failures.

Most importantly, the test was conducted, witnessed, and certified by UL Solutions in compliance with UL 9540A and NFPA 855. Representatives from customers and the U.S fire protection engineer were present on-site, and the entire process was documented through continuous video coverage to ensure complete transparency. This third-party validation confirms that HiTHIUM’s energy storage safety architecture is backed by data and sets a new standard for accountability in battery system design.

Inside HiTHIUM’s Multi-Layered Safety Architecture

By combining structural barriers from the cell to the full container and prioritizing passive over active fire protection, HiTHIUM builds in safety at every level of its energy storage systems.

Layered Barriers: Cell, Pack, System

To contain thermal events at every stage, HiTHIUM adopts a multi-layered fire safety design across the cell, pack, and system levels.

Cell level:

Heat-resistant materials and electrolyte additives increase the thermal failure threshold, reducing the risk of cell-level runaway.

Pack level:

Insulation layers and sealed, flame-retardant covers block heat transfer and oxygen ingress, preventing internal fire spread.

System level:

High-strength, heat-tolerant container structures and built-in fire gaps stop deformation and cross-container propagation.

Passive Containment Beats Active Suppression in Big Systems

Passive containment relies on structural design elements, such as fire-resistant materials, thermal insulation, and strategic spacing, to limit fire spread. In contrast, active suppression systems use gas or liquid agents to extinguish flames after ignition.

During our open-door fire test, all active suppression systems were deliberately disabled. Yet, thanks to the system’s passive safety architecture, the fire was fully contained with no propagation to neighboring units. This demonstrates a key advantage of passive strategies: in large-scale systems, where suppression agents may take time to reach every cell, stopping the spread at the source is faster and more reliable.

Fifteen hours of fire, no structural failure, our open-door test proves why passive safety comes first.

Battery Fire Testing

Why It Matters for Utility-Scale Energy Storage

Optimized Procurement and Siting

HiTHIUM’s open-door fire test demonstrated that even under extreme conditions—including 1,300°C flames burning for 15 hours with doors wide open and only 15 cm spacing between units—the fire remained contained within the initiating container.

This proven containment allows utilities to safely site battery racks closer together, reducing land requirements and associated costs without compromising compliance with local setback regulations. For procurement teams, this data provides concrete assurance that HiTHIUM’s systems lower project risk well before construction begins.

Meeting and Exceeding Safety Standards

Certified by UL Solutions under UL 9540A and NFPA 855, HiTHIUM’s fire safety architecture goes beyond current regulatory requirements. Its multi-layered barriers at the cell, module, and system levels prevent thermal propagation through passive containment, reducing reliance on active suppression systems. This distinction is critical as energy storage installations grow larger, demanding more robust, inherently safe designs.

Mitigating Risks in High-Density Installations

As battery energy storage systems scale to hundreds of megawatt-hours, risk mitigation becomes paramount. HiTHIUM’s proven passive containment approach limits fire spread even in tightly packed installations, minimizing potential damage and enhancing overall system reliability. This leadership in safety innovation sets a new benchmark for managing fire risks in high-density utility-scale projects.

Conclusion

HiTHIUM’s groundbreaking all-open-door fire test provides crucial insights into battery fire behavior under real-world, extreme conditions. The fact that flames remained confined within a single container for hours, thanks to coordinated cell, pack, and system-level barriers, highlights the importance of proactive, multi-layered fire safety design. This test challenges traditional closed-door methods by revealing how passive containment and effective battery thermal management can prevent fire spread before suppression systems are even needed.

By pushing the boundaries of battery fire testing, HiTHIUM is setting new industry standards for safety and reliability. To learn more about HiTHIUM’s innovative fire-safe solutions and how they can enhance your energy storage projects, visit our product portfolio to see what’s possible.

Reference

[1]. Fire breaks out in Escondido SDG&E battery storage facility. https://fox5sandiego.com/news/local-news/fire-breaks-out-in-escondido-sdge-battery-storage-facility/ (Accessed on July 24, 2025)